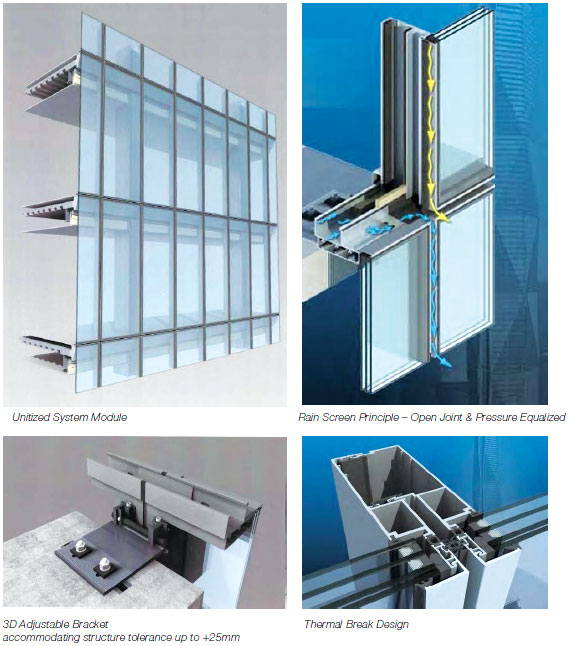

Unitized Curtain Walls is factoryassembled and glazed, then shipped to the job site in units that are typically one lite wide by one floor height. Only one unit-to-unit splice (usually a silicone sheet or patch) needs to be field-sealed, and only one anchor per mullion needs to be attached to the face or top of the floor slab. Interlocking unitized curtainwall frame members are weatheripped to seal to one another, both horizontally and vertically. This accommodates thermal expansion and contraction, inter-story differential movement, concrete creep, column foreshortening, and/or seismic movement. Most unitized curtainwall systems are installed in a sequential manner around each floor level, moving from the bottom to the top of the building.

< Back